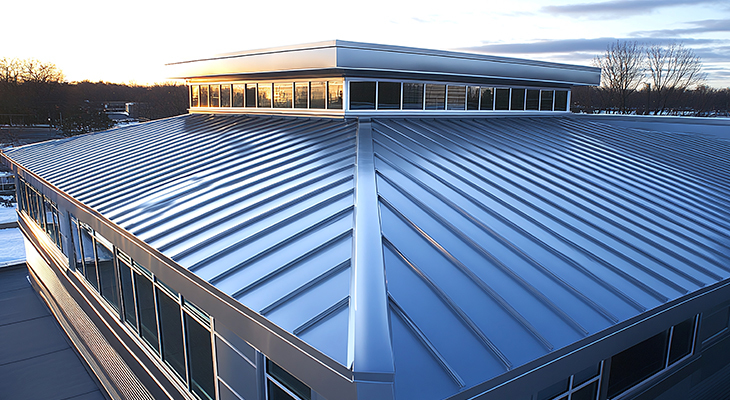

In Edmonton’s fast-changing commercial market, business owners and property managers are investing in roofing systems that last longer and perform better. Metal roofing has become the preferred choice for many due to its resilience, low maintenance, and energy efficiency.

A professional commercial metal roof installation in Edmonton requires more than just technical skill — it takes detailed planning, safety-first practices, and precise coordination.

Stahl Roof Systems has long helped Alberta businesses complete roofing projects on time and within scope while maintaining the highest quality standards. This guide explains what to expect during each phase of a commercial metal roof installation so you can prepare confidently.

Planning the Project: Site Evaluation and Material Selection

Every successful roofing project begins with a thorough site evaluation. Certified contractors inspect the existing roof, assess its load capacity, and identify potential structural concerns.

During this phase, teams also determine which materials best meet the property’s needs. Steel panels are a popular option in Edmonton because they stand up to heavy snow and wind. Aluminum panels, on the other hand, provide corrosion resistance for facilities exposed to moisture or chemicals.

Local building codes and energy standards are key considerations as well. Edmonton’s climate demands roofing materials that can handle temperature fluctuations, which is why metal panels with reflective coatings are often recommended for improved energy efficiency.

Professional contractors also provide cost estimates and timelines at this stage, helping property owners align the project with budget and operational requirements.

Design and Scheduling for Efficiency

Once the site evaluation is complete, the next step is detailed project design. The contractor drafts installation plans, reviews structural drawings, and ensures compliance with municipal permits and safety standards.

Scheduling is carefully coordinated to reduce business interruptions. Installation teams work around peak operating hours whenever possible and factor in weather forecasts to avoid delays.

Digital project management tools are commonly used to track progress, ensuring materials, labour, and inspections align with the overall project schedule. This planning phase is where experience truly pays off — the right approach minimizes downtime and maintains productivity.

Prioritizing Safety and Site Preparation

Before any work begins, safety becomes the top priority. The roofing area is secured using guardrails, harness points, and signage to prevent unauthorized access.

Teams conduct a full safety orientation, reviewing fall protection procedures and site-specific hazards. Alberta’s COR-certified contractors follow Occupational Health and Safety (OHS) regulations to ensure every technician is trained, equipped, and protected.

Site preparation also includes setting up scaffolding, clearing access routes, and staging materials for efficient movement.

Proper organization at this stage not only enhances safety but also keeps the installation on schedule.

Tear-Off or Retrofit: Choosing the Right Approach

Depending on the condition of the existing roof, the contractor will recommend one of two installation methods: a tear-off or a retrofit.

- Full tear-off: The existing roof is completely removed. This allows the crew to inspect the decking for corrosion or damage before installing the new system. It’s the best option for older roofs that have reached the end of their lifespan.

- Retrofit installation: A new metal roofing system is installed over the existing one when the structure is still sound. This reduces waste and shortens the project timeline while maintaining the building’s weather protection.

The choice between these methods depends on inspection results, building codes, and project budgets. A professional roofing contractor will guide you through the pros and cons of each to determine the safest and most cost-effective option.

Panel Installation and Weatherproof Sealing

After preparation, crews begin installing the metal panels. Each panel is precisely measured, cut, and fastened to ensure alignment and structural integrity. Standing seam systems are often used in commercial settings because their interlocking seams create watertight seals that protect against Edmonton’s snow and wind.

Underlayment and insulation layers are added for additional protection and thermal performance. Fasteners are tightened to manufacturer specifications to prevent future leaks, and flashing is applied around edges, vents, and skylights to seal every joint.

During installation, supervisors perform regular quality control checks, verifying panel placement and seam integrity to ensure a consistent, professional finish.

Finishing Touches and Quality Assurance

Once the panels are secured, contractors move on to finishing details. Flashing is installed around perimeters, fasteners are double-checked, and protective coatings are applied to improve longevity and appearance.

Quality assurance testing is the final checkpoint. Water penetration tests and visual inspections confirm that seams, joints, and edges are properly sealed. These final checks give business owners confidence that their new metal roof will perform optimally for decades.

This phase is also when contractors document the materials used, safety compliance, and installation notes for warranty and maintenance records.

Cleanup, Inspection, and Handover

A professional roofing team ensures that no debris, screws, or leftover materials remain on-site. Scaffolding, safety barriers, and waste bins are removed once the area is inspected for cleanliness and safety.

After the cleanup, the contractor conducts a final walkthrough with the property owner or manager. This includes reviewing warranty terms, explaining recommended maintenance schedules, and verifying that all project specifications have been met.

For most projects, warranties cover both materials and workmanship, giving building owners long-term protection and peace of mind.

Typical Project Timeline

The timeline for a commercial metal roof installation varies depending on size, complexity, and weather. As a general guide:

- Small commercial buildings (under 10,000 sq. ft.): 1–2 weeks

- Medium facilities (10,000–30,000 sq. ft.): 3–4 weeks

- Large industrial complexes: 5–6 weeks or more

Factors such as crew size, material availability, and Edmonton’s seasonal conditions may extend the schedule slightly.

The most efficient projects are those that begin with proactive planning, clear communication, and timely material procurement.

Common Challenges and How Professionals Manage Them

Commercial roofing projects can face challenges ranging from unpredictable weather to logistical constraints.

Experienced contractors anticipate these risks and build flexibility into the schedule. For example, during Edmonton’s colder months, teams may work in shorter shifts to manage freezing conditions safely.

Coordination with other trades — such as HVAC technicians or electrical contractors — is also essential to avoid conflicts on the worksite.

Professional communication, daily progress updates, and documented safety checks ensure the project continues smoothly despite unforeseen issues.

The Value of Hiring Certified Roofing Contractors

Commercial metal roof installation is a complex process that demands experience, specialized tools, and strict adherence to safety standards. Hiring uncertified contractors may lead to delays, code violations, or warranty voids.

Certified roofing professionals bring the assurance of tested systems, proven techniques, and compliant safety practices. They also maintain transparent project documentation and guarantee material traceability — key factors for long-term value and building insurance compliance.

For property owners in Edmonton, choosing a reputable metal roofing contractor ensures reliability, compliance, and measurable return on investment.

Trusted Experts in Commercial Metal Roofing

Stahl Roof Systems is a trusted name in metal roofing across Edmonton and Alberta, providing durable, energy-efficient solutions for commercial, industrial, and residential properties.

With years of experience and a strong focus on craftsmanship, the company ensures that every project meets the highest standards of safety and quality.

Learn more about professional commercial metal roof installation services or contact our team to request an estimate and schedule your consultation.